February 24, 2025

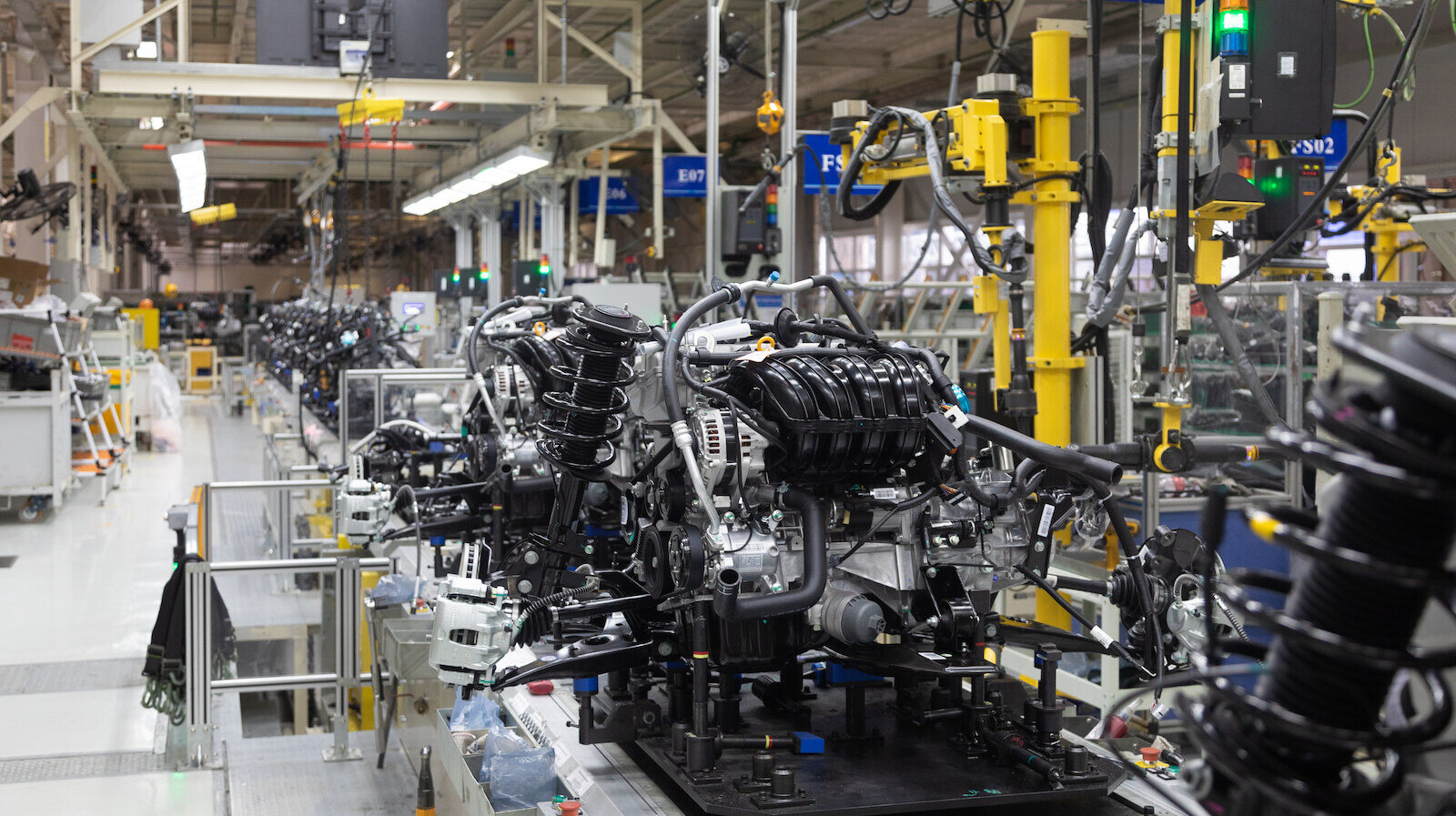

Criteria for Selecting the Best Automotive Steel Wire in Manufacturing

In automotive manufacturing, selecting the right kind of steel wire is essential to ensure the durability, efficiency, and quality of the final product. Having a reliable steel wire supplier not only provides security regarding the materials but also guarantees the dependability and precision of production results.

Choosing the best supplier requires careful consideration of various factors, such as product properties, manufacturing processes, quality control, and the standards and certifications that automotive steel wire must meet.

In this article, we cover the main criteria for selecting automotive steel wire according to experts at Deacero Summit. Read on to learn more.

Key Properties of Automotive Steel Wire

Automotive steel wire is fundamental in automotive manufacturing due to its key properties: high tensile strength and durability. These qualities allow for the production of automotive components that withstand extreme loads and tolerate adverse conditions, which in turn enhances the safety and performance of vehicles.

- High tensile strength: Ensures that the material does not break or deform easily under the pressure of heavy loads.

- Durability: Extends the lifespan of components, reducing the need for frequent replacements due to operational failures.

Additionally, the flexibility and ductility of steel wire enable its use in various applications within the automotive industry, ranging from structural parts like screws, bolts, shafts, and gears to suspension and steering systems.

Together, these properties make automotive steel wire an ideal choice for car manufacturers who prioritize the reliability and efficiency of materials. However, they also highlight the importance of understanding the international regulations and standards that validate the required quality level for automotive manufacturing.

Which Standards and Certifications Should It Have?

%20(1).jpg?width=600&height=400&name=certification-standards-iso-business-certification-international-standards%20(1)%20(1).jpg)

International quality standards and certifications, such as ISO 9001 and IATF 16949, are crucial for ensuring the quality of automotive steel wire.

- ISO 9001 Certification: Establishes principles for managing consistent and effective quality systems in industrial and organizational settings.

- IATF 16949 Certification: Adds specifications for the automotive manufacturing sector regarding the development of quality management systems and continuous improvement.

Selecting a steel wire supplier that meets these certifications offers numerous benefits, such as the assurance of high-quality products, the reduction of defects, and the mitigation of potential risks during automotive manufacturing.

ISO 9001 and IATF 16949 certifications are relevant because they provide a framework for optimized and controlled production processes in the manufacturing of automotive steel wire, increasing customer confidence in the finished product.

Production Process and Quality Control

While compliance with these certifications enhances the reliability of steel wire, ensuring that it meets the most demanding performance requirements and withstands usage conditions in various automotive manufacturing applications, it is necessary for the production process of this material to undergo a quality control phase.

Conducting specialized tests to evaluate the quality of the wire, such as those for hardness, tension, and compression, metallographic analyses with a digital microscope, and determination of chemical elements with a digital spectrometer, ensures superior results.

Moreover, implementing a traceability system allows for the maximization of international quality standards by using unique identification records.

Advanced Manufacturing Technologies

Advanced technologies in the production of automotive steel wire significantly enhance its properties and performance. Similarly, their widespread use has driven optimization and efficiency in automotive manufacturing processes.

The integration of cutting-edge technology helps produce high-quality steel wires that meet international standards and automotive sector certifications, thereby improving the competitiveness of suppliers in the global market.

Some of the most important innovations in automotive manufacturing technology used to produce automotive steel wire include:

- Advanced Coatings: Technologies such as hot-dip galvanizing and polymer coatings provide additional protection against corrosion.

- Automated Quality Control: Inspection systems with artificial vision and real-time analysis to detect defects and ensure product consistency.

- Innovative Heat Treatments: Processes like annealing and surface hardening treatments improve the mechanical properties of the wire.

- Precision Drawing Technology: State-of-the-art drawing equipment ensures exact dimensions and high surface quality.

5 Steps to Selecting a Steel Wire Supplier

Now that you know more about the properties, certifications, and manufacturing of automotive steel wire, are you ready to select a supplier for your company?

Here are 5 steps to help you choose the best steel wire supplier for your automotive manufacturing needs:

- Research the Supplier’s Reputation: Investigate their history and consult customer reviews to ensure that the supplier is reliable and has a proven track record with solid experience in automotive manufacturing.

- Evaluate Product Quality: Verify that the automotive steel wire they offer complies with international standards and quality certifications, such as ISO 9001 and IATF 16949. The quality of the steel wire for automotive manufacturing is crucial to guarantee the durability and performance of the final product.

- Review Production Capacity: Ensure that the supplier has the capability to meet your company’s required deadlines and quantities. Advanced automotive manufacturing technology ensures efficiency and consistency.

- Verify Logistics Efficiency: Efficient logistics are fundamental to ensuring a continuous supply of materials. Evaluate the supplier’s distribution network and their ability to handle timely and uninterrupted deliveries.

- Analyze Support and Customer Service: A good supplier not only offers a quality product but also excellent support and customer service. Verify that the supplier is available to resolve queries, offer technical advice, and provide quick solutions to any issues that may arise.

%2012.53.06%20p.m..jpg?width=600&height=396&name=Captura%20de%20pantalla%202025-01-24%20a%20la(s)%2012.53.06%20p.m..jpg)

Selecting the right steel wire supplier is crucial to ensuring quality and efficiency in automotive manufacturing. A steel wire supplier that employs advanced technologies in automotive manufacturing offers significant advantages in terms of safety, efficiency, and the performance of the final product.

At Deacero Summit, we are driven by experience and a commitment to the highest quality. Our automotive steel wire is backed by international certifications and years of innovation in automotive manufacturing technology.

Learn more about our industrial steel wire offer and discover why our products are the solution to your automotive manufacturing needs.

Contact our team of experts today and receive personalized advice promptly.