Innovation in the aerospace industry is a cornerstone of technological advancement and global competitiveness. Modular construction has emerged as a transformative solution within this sector, addressing efficiency and sustainability challenges while meeting rigorous precision standards.

In this article, we’ll explore modular construction in aerospace, its various applications in aeronautical architecture, and how it supports innovation in the aerospace industry. Let’s dive in!

What is Modular Construction?

Modular construction is a building methodology where structures are created using prefabricated, lightweight components. These modules are easy to transport and assemble, making them ideal for common spaces such as:

- Warehouses

- Office cubicles

- Classrooms

- Additional hospital areas

- Security booths

This system is not only efficient but also flexible and highly customizable—key attributes in sectors requiring unmatched precision, such as aerospace construction.

Applications of Modular Construction in Aerospace Architecture

Modular construction has moved beyond terrestrial applications, finding a critical role in the aerospace industry, where precision and efficiency are essential. Below are some of its most impactful uses:

1. Aircraft Assembly

In aerospace modular construction, aircraft manufacturing benefits from modular assembly systems. Components like wings, fuselage, and propulsion systems are produced in separate facilities and later assembled on a central production line.

This approach optimizes production timelines while reducing errors, as each module adheres to strict quality standards. The result is a safer and more efficient assembly process that streamlines aerospace innovation.

2. Satellite Construction

Building satellites requires highly specific structural and functional components. Here, modular space construction systems offer significant advantages. Each module can be designed to fulfill a specific function, ensuring precision throughout the project.

Additionally, the modular design enhances adaptability. Satellite subsystems, such as command modules, can be reconfigured based on mission requirements, improving efficiency and flexibility.

3. Spacecraft and Mission Capsules Design

Spacecraft components must withstand extreme conditions, including intense radiation, temperature fluctuations, and vacuum environments. Modular construction systems ensure these components are optimized for performance and reliability.

Benefits of modular systems in spacecraft design include:

- Reduced assembly risks during final integration.

- Enhanced maintenance and upgrade processes through rapid disassembly and reassembly.

By improving efficiency, modular space architecture ensures each system functions flawlessly in extraterrestrial environments.

4. Space Exploration Projects

Advancements in aerospace innovation now enable the creation of space habitats and stations using modular construction systems. These modules are preassembled, launched into space, and adapted to meet the unique conditions of the environment.

This method is transforming space architecture by creating scalable, sustainable systems for long-term missions.

Benefits of Modular Construction in Aerospace

Modular construction brings numerous benefits to the aerospace industry:

- Cost and Time Efficiency: Prefabricated modules shorten project timelines and reduce costs.

- Sustainability: Reusable modules minimize material waste and environmental impact.

- Flexibility and Adaptability: Modular systems allow for easy adjustments and customization based on mission requirements.

- Safety: Rigorous module design reduces risks and ensures optimal performance at all stages.

Deacero Summit: Your Partner for High-Quality Materials

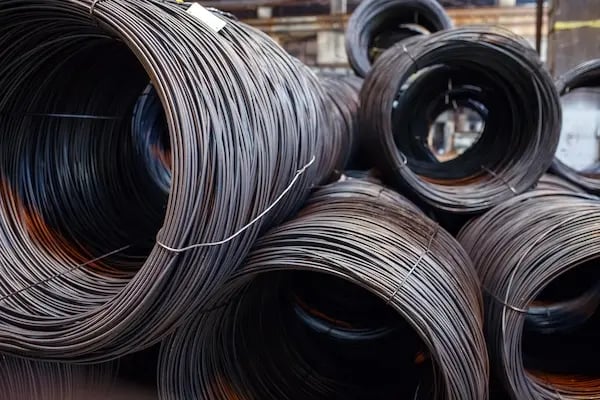

For the aerospace industry to achieve success, it requires materials that deliver exceptional durability and performance. At Deacero Summit, we provide aerospace-grade steel wire that meets the highest quality standards.

Our steel wire incorporates advanced innovations to ensure:

- Maximum resistance

- Superior flexibility

- Optimal load-bearing capacity

These attributes are critical for applications such as aircraft assembly and the development of space systems.

By choosing Deacero Summit, you’re investing not only in durable, high-performance materials but also in a sustainable future for the aerospace industry.

Ready to Take Off?

Modular construction is revolutionizing the aerospace industry, and high-quality materials are the foundation of its success. At Deacero Summit, we offer innovative steel wire solutions that support even the most ambitious aerospace projects.

Discover how our products can help you elevate your ideas to new heights! Contact us today and explore our full range of aerospace steel wire solutions.